For device tagging and wire numbering

%F Component family code string (for example, "PB", "SS", "CR", "FLT", "MTR")

Family codes can easily be modified at a global level. See Mark's paper on this here... wd_fam.dat

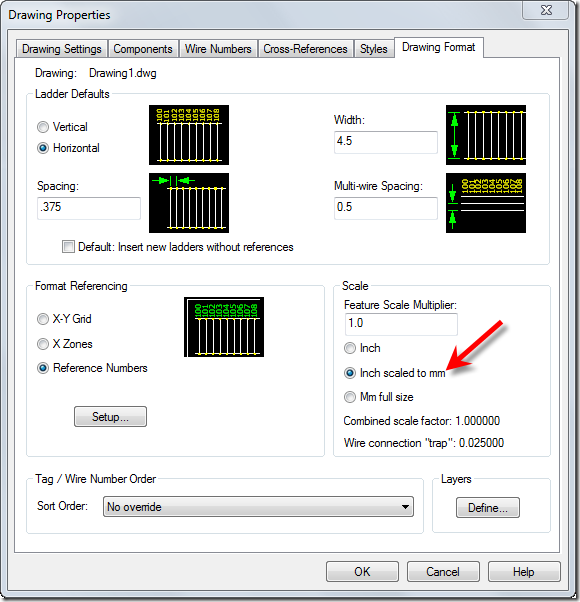

%S Drawing's sheet number (for example, "01" entered in upper right)

%D Drawing number

%G Drawing's wire layer name

%N Sequential or Reference-based number applied to the component

%X Suffix character position for reference-based tagging (not present = end of tag)

%P IEC-style project code (default for drawing)

%I IEC-style installation code (default for drawing)

%L IEC-style location code (default for drawing)

%A Project drawing list's SEC value for active drawing

%B Project drawing list's SUB-SEC value for active drawing

Examples of Component Tags

For a light on sheet 3 rung 50

%F%N = LT50 (Default)

%F%S/%N = LT3/50

%F-%S-%N = LT-3-50

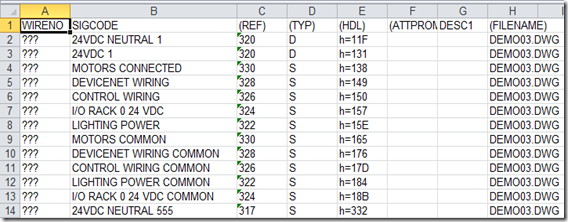

Examples of a Wire

For a line reference 100 of sheet 02

%N wire number = 100 (Default)

W%N wire number = W100

%S-%N wire number = 02-100

%S%N wire number = 02100

%S : %N wire number = 02:100

Note: For %S and %D to work the sheet and drawing fields must be entered in the drawing properties.

For defining wire annotation and graphical terminal strips

%P Terminal pin text

%Q Terminal pin TERMDESC text

%I IEC-style function/installation code

%L IEC-style location code

%M Mount assignment (on panel footprint equivalent)

%U Group assignment (on panel footprint equivalent)

%W Wire number

%C Cable tag + conductor/core color combination (format is "tag-color")

%E Cable tag

%J Cable conductor/core color

%V Cable tag substituted for wire number if cable tag is non-blank.

The wire number is displayed when a cable ID doesn't exist.

%G Wire color/gauge (or wire layer name)

%H Cable wire color substituted for wire number if cable color is non-blank.

The wire layer is displayed when a wire conductor in conjunction with a cable ID doesn't exist.

%T Terminal strip terminal pin assignment

%K Terminal strip TERMDESC text - useful for multi-stack terminals

%1 Destination component tag ID. You can use only one of the (%number) parameters.

%2 Equivalent of "%1:%P" (comp tag:term)

%3 Equivalent of "%1:%P:%D" (comp tag:term:termdesc)

%4 Equivalent of "%L%1" (IEC comp tag)

%5 Equivalent of "%L%1:%P" (tag:term)

%6 Equivalent of "%L%1:%P:%D" (tag:term:termdesc)

%7 Equivalent of "%I%I%1" (INST prefix+IEC comp tag)

%8 Equivalent of "%I%L%1:%P" (tag:term)

%9 Equivalent of "%I%L%1:%P:%D" (tag:term:termdesc)

The part after the colon(:) is suppressed if the value is blank in %2 - %9 parameters (for example, %2=comp tag:term). The ":term" part is suppressed if blank.